ISO 23296:2022 pdf download – Metallic materials – Fatigue testing – Force controlled thermo-mechanical fatigue testing method.

1 Scope This document applies to stress and/or force-controlled thermo-mechanical fatigue (TMF) testing. Both forms of control, force or stress, can be applied according to this document. This document describes the equipment, specimen preparation, and presentation of the test results in order to determine TMF properties. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 7500-1, Metallic materials — Calibration and verification of static uniaxial testing machines — Part 1: Tension/compression testing machines — Calibration and verification of the force-measuring system ISO 12111, Metallic materials — Fatigue testing — Strain-controlled thermomechanical fatigue testing method ISO 23788, Metallic materials — Verification of the alignment of fatigue testing machines 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. ISO and IEC maintain terminology databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https://www.iso .org/obp — IEC Electropedia: available at https://www.electropedia .org/ 3.1 force F force applied to the test section, in kN Note 1 to entry: Tensile forces are considered to be positive and compressive forces negative. 3.2 maximum force F max highest algebraic value of force applied, in kN 3.3 minimum force F min lowest algebraic value of force applied, in kN

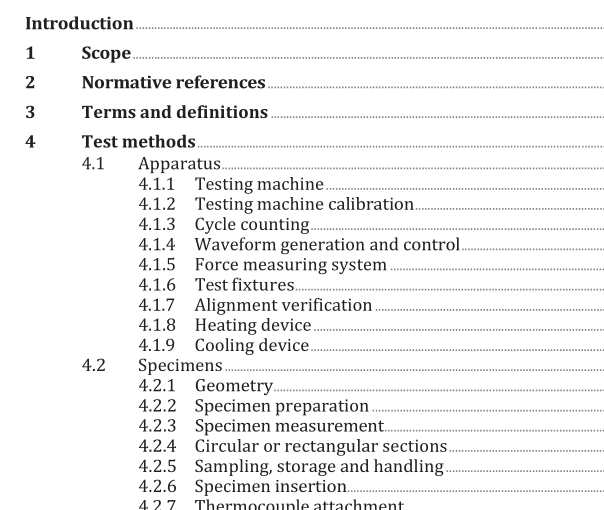

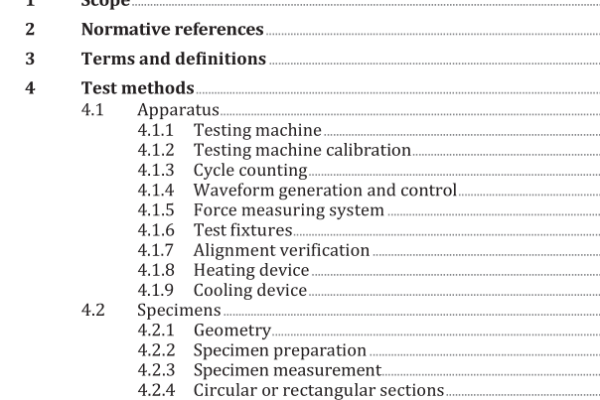

4 Test methods 4.1 Apparatus 4.1.1 Testing machine The tests shall be carried out on a tension-compression machine designed for a smooth start-up. All test machines are used in conjunction with a computer or controller to control the test and log the data obtained. The test machine shall permit cycling to be carried out between predetermined limits of force to a specified waveform and for R < 0 tests there shall be no discernible backlash when passing through zero. In order to minimise the risk of buckling of the specimen, the machine should have great lateral rigidity and accurate alignment between the test space support references. The machine force indicator shall be capable of displaying cyclic force maxima and minima for applied waveforms to a resolution consistent with the calibration requirement. During elevated temperature tests the machine load cell shall be suitably shielded and/or cooled such that it remains within its temperature compensation range. Machines employing closed loop control systems for force and temperature shall be used.

ISO 23296:2022 pdf download – Metallic materials – Fatigue testing – Force controlled thermo-mechanical fatigue testing method