ISO 15208:2022 pdf download – Continuous hot-dip zinc-coated twin- roll cast steel sheet of commercial quality.

1 Scope This document specifies the requirements for steel sheet, in coils and cut length, metallic-coated by the continuous hot-dip zinc-coated twin-roll cast process of commercial quality. The steel sheet is intended for applications requiring corrosion resistance, formability and paintability. The steel sheet is produced in a number of grades, coating masses, surface treatments and ordering conditions. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 1460, Metallic coatings — Hot dip galvanized coatings on ferrous materials — Gravimetric determination of the mass per unit area ISO 2178, Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method ISO 3497, Metallic coatings — Measurement of coating thickness — X-ray spectrometric methods ISO 6892-1, Metallic materials — Tensile testing — Part 1: Method of test at room temperature ISO 7438, Metallic materials — Bend test ISO 16163, Continuously hot-dipped coated steel sheet products — Dimensional and shape tolerances 3? Terms? and? definitions For the purposes of this document, the following terms and definitions apply. ISO and IEC maintain terminology databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https:// www .iso .org/ obp — IEC Electropedia: available at https:// www .electropedia .org/ 3.1 commercial quality base-metal quality intended for general fabricating purposes where sheet is used in the flat condition, or for bending or moderate forming 3.2 continuous hot-dip zinc-coated steel sheet product in coils or cut lengths manufactured on a continuous coating line with a hot-dip zinc coating on base-metal of cold-reduced or hot-rolled descaled steel

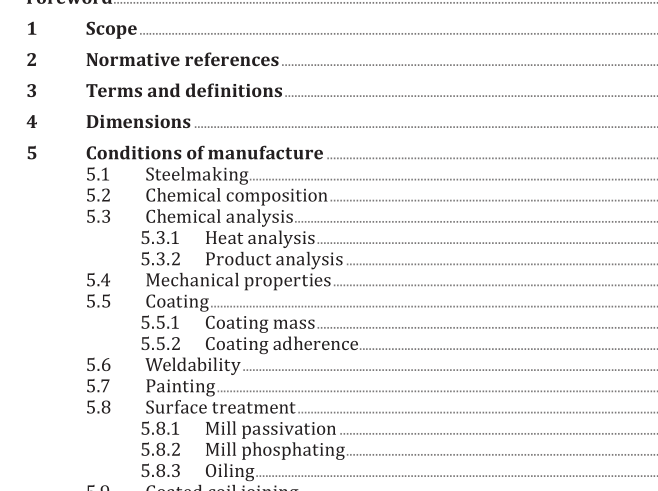

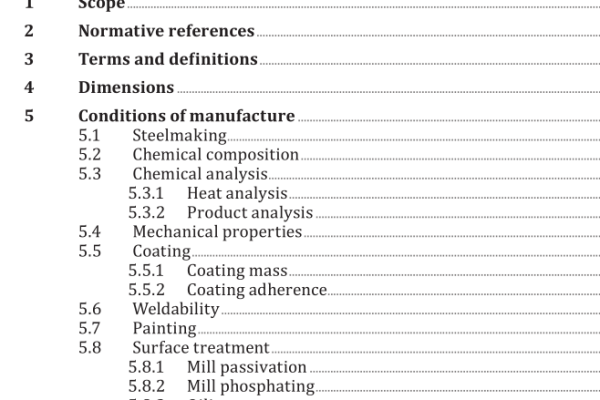

5 Conditions of manufacture 5.1 Steelmaking Unless otherwise agreed by the interested parties, the processes used in making the steel and in manufacturing zinc-coated steel sheet are left to the discretion of the manufacturer. Upon request, the purchaser shall be informed of the steelmaking process being used. 5.2 Chemical composition The chemical composition (heat analysis) shall conform to the requirements given in Tables 1 and 2. 5.3 Chemical analysis 5.3.1 Heat analysis An analysis of each heat shall be made by the manufacturer in order to determine conformity with the requirements given in Tables 1 and 2. On request, a report of the heat analysis shall be made available to the purchaser or the purchaser’s representative. Each of the elements listed in Tables 1 and 2 shall be included in the report of the heat analysis. When the amount of copper, nickel, chromium or molybdenum present is less than 0,02 %, the analysis may be reported as “<0,02 %”. 5.3.2 Product analysis A product analysis may be made by the purchaser in order to verify the specified analysis of the product and shall take into consideration any normal heterogeneity. The product analysis tolerances shall be in accordance with Tables 2 and 3.

ISO 15208:2022 pdf download – Continuous hot-dip zinc-coated twin- roll cast steel sheet of commercial quality