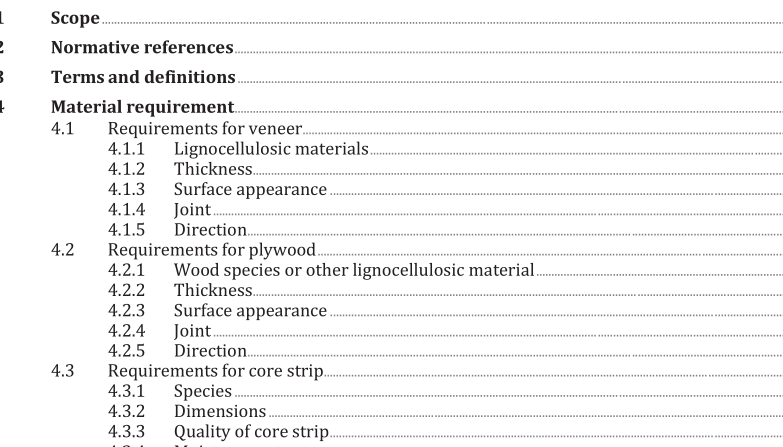

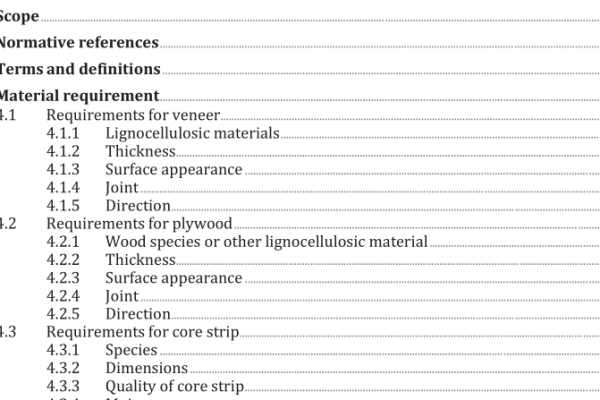

ISO 13609:2021 pdf download – Wood-based panels — Plywood — Blockboards and battenboards.

4.2.2 Thickness The thickness of plywood shall be greater than or equal to 3,0 mm. 4.2.3 Surface appearance The surface appearance of plywood shall be controlled. Surface appearance of the face layer shall satisfy the criteria defined for class II, as given in ISO 2426-2:2020, Table 1 or in ISO 2426-3:2000, Table 1 or in ISO 2426-4:2018, Table 1. 4.2.4 Joint Jointed plywood is not permitted when used for surface layers. 4.2.5 Direction The direction of the grain of the veneer glued to the core shall be determined by considering the veneer lay-up of the plywood. 4.3 Requirements for core strip 4.3.1 Species Within a panel, all strips should be made from the same species. If there are more than one species, similar physical property is required. Otherwise, there shall be an agreement between involved parties. 4.3.2 Dimensions For the blockboard, the width, w, of the strip shall be 7 mm ≤ w ≤ 30 mm. For the battenboard, the width, w, of the strip shall be 30 mm < w ≤ 76 mm. There is no limitation for strip length. The thickness of each strip should not be less than 8,0 mm within a tolerance of ±0,1 mm. Each piece of core strip shall be sized in thickness, individually or after assembly into the core plate. The ratio of width to thickness of each strip should not exceed 3,5. 4.3.3 Quality of core strip Each piece of core strip shall meet the quality requirements as follows: — for sound knot, the maximum of diameter shall not exceed 25 mm or 80 % of the width of the strip, whichever is lesser; — for intergrown knot or encased knot, the maximum diameter shall not exceed 15 mm or half of the width of the strip, whichever is lesser; — for gum pocket, resin pocket, and bark pocket, the width shall not exceed 3 mm; — for want or wane, the width shall not exceed 5 mm on the core face and the length shall not exceed 20 mm. 4.3.4 Moisture content Moisture content of the core strip shall be between 8 % and 12 % at the time of assembling.

4.4 Requirements for core strip assembly 4.4.1 Direction of core strip The length direction of the strip shall be parallel or nearly parallel to the long edge of the board. 4.4.2 Jointing assembly in the length direction of core strip For jointed strip, following criteria shall be satisfied: — any joint seam shall not be wider than 1 mm; — the distance between any two adjacent seams shall not be less than 50 mm; — for finger jointing or scarf jointing, the slope of the scarves shall not be steeper than 1 in 8. 4.4.3 Jointing assembly in the width direction of core strip In width direction, the core strips could be glued or unglued and the following criteria shall be satisfied: — gap between solid wood strips shall not exceed 1,5 mm; — in any 1 000 mm in the width direction of core strip, the sum of gaps shall not exceed 6 mm. 4.4.4 Thickness and tolerance Determination of thickness and tolerance of the core plate shall be carried out in accordance with ISO 9426 and ISO 1954. 4.5 Adhesives Except the adhesive used for bonding core strips in width direction, the adhesive used for combination with the veneers, plywood, and core shall provide the board performance necessary to satisfy the requirements for bond type as specified in Clause 7. Bonding strength and durability of the adhesives applied to finger jointing and scarf jointing veneers and strips shall not be inferior to the criteria defined above. Any glue failure is not permitted in transverse modulus of rupture test. 5 Panel lay-up and manufacturing requirements The lay-up shall be controlled, including the thickness, orientation, wood species, and quality of veneers. NOTE Any other characteristics can be required and added as in contract, if necessary.

ISO 13609:2021 pdf download – Wood-based panels — Plywood — Blockboards and battenboards