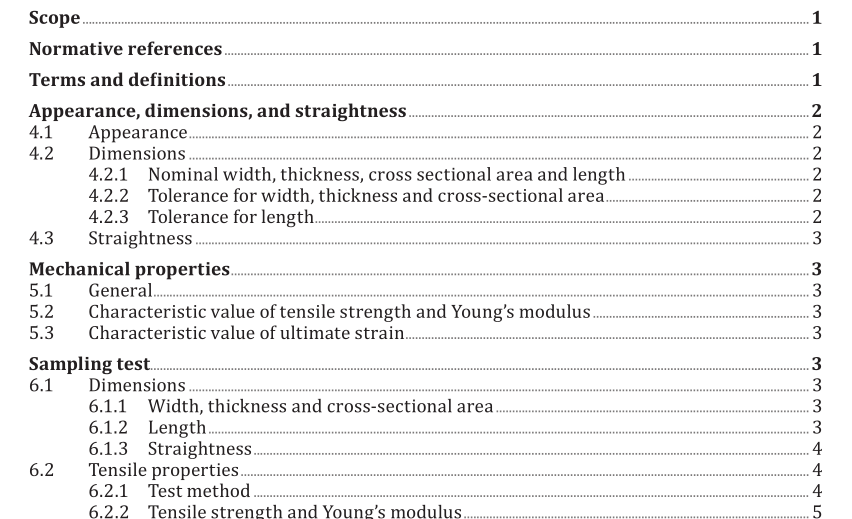

ISO 18319-2:2022 pdf download – Fibre reinforced polymer (FRP) reinforcement for concrete structures — Part 2: Specifications of CFRP strips.

4.3 Straightness Tolerance of straightness in sampling test specified in Clause 6 shall not be larger than 0,5 mm. 5 Mechanical properties 5.1 General The mechanical properties of CFRP strips shall be expressed by the characteristic values of tensile strength, Young’s modulus, and ultimate strain. NOTE This requirement is to be met by the manufacturer of the product. The properties for design are calculated from the characteristic values, as prescribed in an appropriate design code which is in accordance with ISO 14484. 5.2 Characteristic value of tensile strength and Young’s modulus The characteristic value of tensile strength and characteristic value of Young’s modulus of CFRP strips shall be agreed between interested parties. 5.3 Characteristic value of ultimate strain The characteristic value of ultimate strain shall be determined by the characteristic value of tensile strength divided by the characteristic value of Young’s modulus. 6 Sampling test 6.1 Dimensions 6.1.1 Width, thickness and cross-sectional area The width of CFRP strips shall be measured with an interval of 10 m in length by a calliper, expressed with a precision of 0,1 mm rounded down to the first decimal place. The thickness of CFRP strips shall be measured with an interval of 10 m in length by a calliper, expressed with a precision of 0,1 mm rounded down to the first decimal place. The cross-sectional area of CFRP strips shall be determined by multiplying the width and the thickness, expressed with a precision of 0,1 mm 2 rounded down to the first decimal place. 6.1.2 Length In case the nominal length is equal to or larger than 5 m, the length of CFRP strips shall be measured by a roller type length measuring device with rolling up the strip, expressed with a precision of 0,1 m rounded down to the first decimal place.

In case the nominal length is smaller than 5 m, the length of CFRP strips shall be measured by a metallic tape measure for the flattened strip, expressed with a precision of 0,01 m rounded down to the second decimal place. 6.1.3 Straightness Straightness of CFRP strips shall be measured in accordance with following procedure. a) Place the flattened strip on a surface plate. b) A metallic scale with 1 m length (long scale) shall be disposed along the axis of the strip. Other metallic scale shall be placed perpendicularly at the central position of the long scale as shown in Figure 1. c) The interstice between the strip and the long scale shall be measured with a precision of 0,1 mm rounded down to the first decimal place.

ISO 18319-2:2022 pdf download – Fibre reinforced polymer (FRP) reinforcement for concrete structures — Part 2: Specifications of CFRP strips