ISO 14246:2022 pdf download – Gas cylinders — Cylinder valves — Manufacturing tests and examinations.

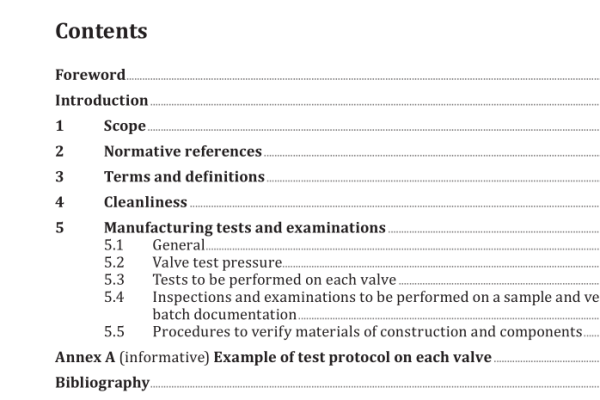

1 Scope This document specifies the procedures and acceptance criteria for manufacturing tests and examinations (sometimes called “initial inspection and tests”) of valves designed and type tested in accordance with ISO 10297. This document is applicable to: a) cylinder valves intended to be fitted to refillable transportable gas cylinders; b) main valves (excluding ball valves) for cylinder bundles; c) cylinder valves or main valves with integrated pressure regulator (VIPR); d) valves for pressure drums and tubes. NOTE Where there is no risk of ambiguity, cylinder valves, main valves, VIPR and valves for pressure drums and tubes are addressed with the collective term “valves” within this document. The principles of these manufacturing tests and examinations can be beneficially applied to cylinder valves type tested to national or International Standards other than ISO 10297. 2 Normative references The following documents are referred to in the text in such a way that some or all of their content constitutes requirements of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. ISO 10286, Gas cylinders — Vocabulary ISO 10297, Gas cylinders — Cylinder valves — Specification and type testing 3? Terms? and? definitions For the purposes of this document, the terms and definitions given in ISO 10286 and the following apply. ISO and IEC maintain terminological databases for use in standardization at the following addresses: — ISO Online browsing platform: available at https:// www .iso .org/ obp — IEC Electropedia: available at https:// www .electropedia .org/ 3.1 valve working pressure p w settled pressure of a compressed gas at a uniform reference temperature of 15 °C in a full gas cylinder for which the valve is intended Note 1 to entry: This definition does not apply to liquefied gases (e.g. carbon dioxide) or dissolved gases (e.g. acetylene). [SOURCE: ISO 10297:2014, 3.6, modified — “or cylinder bundle” has been deleted from the definition and Note 2 to entry has been deleted.]

3.2 valve test pressure p vt minimum pressure applied to a valve through a gas during testing [SOURCE: ISO 10297:2014, 3.8, modified — “through a gas” has been added to the definition and the note to entry has been deleted.] 3.3 external leak tightness leak tightness to atmosphere (leakage in and/or leakage out) when the valve is open [SOURCE: ISO 10297:2014, 3.4, modified — Note 1 to entry and Figure 1 have been deleted.] 3.4 internal leak tightness leak tightness across the valve seat (leakage in and/or leakage out) when the valve is closed [SOURCE: ISO 10297:2014, 3.5, modified — Note 1 to entry and Figure 2 have been deleted.] 3.5 batch quantity of valves of the same type tested design and production order, which is produced as a controlled number in a specified time period 3.6 sample quantity of valves selected from a batch (3.5) according to a recognized sampling procedure Note 1 to entry: The ISO 2859 series specifies sampling procedures for inspection. 4 Cleanliness The manufacturing process including all tests shall be such that the valves are supplied clean and dry to meet the requirements of the intended service, e.g. see ISO 15001 for medical applications. Gas wetted components of valves for oxygen and other oxidizing gases (see ISO 10156) shall be clean of oil and grease so that the level of hydrocarbon contamination is not greater than 220 mg/m 2 . In addition, components shall be free from particles of a size larger than 200 µm. This shall be verified by an appropriate method, e.g. as given in ISO 15001. Consideration shall be given to minimize the introduction of particles and the risk of contamination during the assembly process.

ISO 14246:2022 pdf download – Gas cylinders — Cylinder valves — Manufacturing tests and examinations