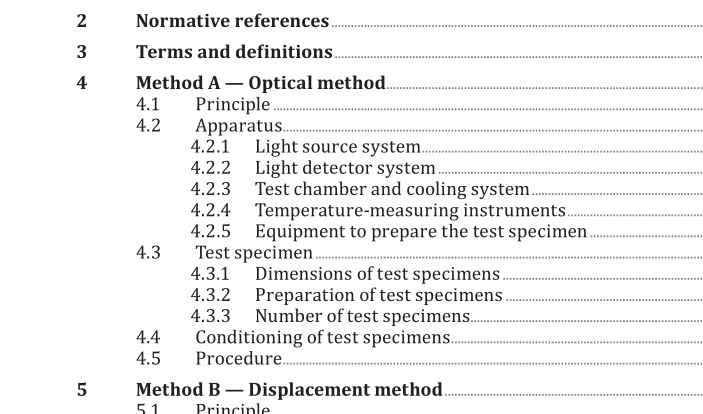

ISO 23766:2022 pdf download – Thermal insulating products for industrial installations — Determination of the coefficient of linear thermal expansion at sub- ambient temperatures.

5.2 Apparatus 5.2.1 Sensor for distance A displacement measurement sensor reading to the nearest 1 µm, with a load less than 50 Pa, shall be used for the measurement of the relevant dimension / length of rigid specimen. For soft insulation products, the required load for the determination of the thickness according to the product standard shall be taken into account. If no product standard exists, the load should be agreed between the involved parties. 5.2.2 Test chamber and cooling system Capable of maintaining the mean temperature of the test specimen to within ±1 K of the desired test temperature below ambient temperature with the possibility to adjust the cooling down rate. NOTE The chamber can be cooled down with liquid nitrogen to reach the cryogenic area. 5.2.3 Temperature-measuring instruments Calibrated temperature-measuring devices suitable for the test with an accuracy of ±0,5 K to determine the mean temperature of the specimen (minimum three sensors over the specimen length in the direction of the displacement measurement). The temperature-measuring devices are connected to a continuous recording device. If only the mean coefficient of linear thermal expansion, α m , between two temperatures is needed, the measurements shall only be carried out at these temperatures. If the full curve over a temperature range is needed, it shall be done in a stepwise way. 5.2.4 Equipment to prepare the test specimen Suitable saw to prepare the test specimen. 5.3 Test specimen 5.3.1 Dimensions of test specimens The dimensions shall be appropriate for the dimensions of the apparatus. Specimens of the dimension 50 mm × 50 mm × thickness (minimum 10 mm to maximum 50 mm) shall be used. Larger dimensions are also possible. The test specimen should be carefully selected to be representative of the product being tested. 5.3.2 Preparation of test specimens Any skins, facings, and/or coatings shall be removed. Test specimens shall be sawn from the product in the direction in which the measurement of the coefficient of linear thermal expansion shall be made and in which the linear dimensions are to be recorded. Special requirements for preparation such as annealing or drying under specified conditions shall be indicated where relevant in the product standard. For anisotropic products, the measurements shall be carried out in all relevant directions.

5.3.3 Number of test specimens The number of test specimens shall be as specified in the relevant product standard. If the number is not specified, then at least two test specimens shall be used. 5.4 Conditioning of test specimens The test specimens shall be stored for at least 6 h at (23 ± 5) °C. In case of dispute, they shall be stored at (23 ± 2) °C and (50 ± 5) % relative humidity (RH) for the time specified in the relevant product standard. In tropical climates, different conditioning and testing conditions can be relevant. In this case, the conditions shall be (27 ± 5) °C and (65 ± 5) % RH.

ISO 23766:2022 pdf download – Thermal insulating products for industrial installations — Determination of the coefficient of linear thermal expansion at sub- ambient temperatures