ISO TS 24498:2022 pdf download – Paper, board and pulps — Estimation of uncertainty for test methods by interlaboratory comparisons.

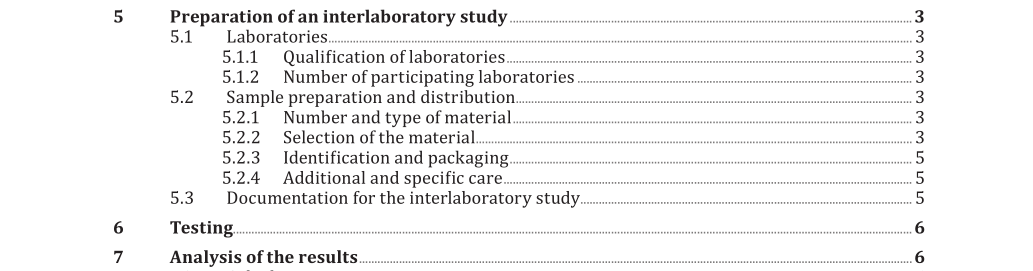

5 Preparation of an interlaboratory study 5.1 Laboratories 5.1.1? Qualification? of? laboratories Any laboratory that would be considered qualified to run the test is permitted and encouraged to participate in the interlaboratory study. Laboratories shall be properly equipped to follow all details of the procedure, including climate conditions when specified, and be willing to assign the work to a skilled operator on a timely basis with competent personnel having knowledge of the materials and of the property to be tested. In many situations it is preferable that participating laboratories meet the requirements of ISO/IEC 17025 [4] or equivalent, or that at least they participate in a comparative testing service and have been shown to be competent in the test for which the precision data is being obtained. The decision on permitting a laboratory to participate should be based on information provided to the working group, including information as to the required time for calibrating the apparatus and for testing all of the materials. 5.1.2 Number of participating laboratories It is recommended to include at least eight laboratories to obtain a valid estimate of the uncertainty associated with the test method. No interlaboratory round robin test should be performed with less than five laboratories. 5.2 Sample preparation and distribution 5.2.1 Number and type of material The number and types of materials to be included in the interlaboratory study should cover the range of the values of the property being measured and be representative of the number of types or classes of materials to which the test method is to be applied. It also should cover each scale of the instrument (e.g. Scott Bond) if applicable. If the interlaboratory study is restricted in any of these areas, the omitted information should be reported in the precision statement. 5.2.2 Selection of the material 5.2.2.1 General The sampling procedure shall be appropriate to the property to be assessed and the type of material (pulp, paper, board or cellulosic nanomaterial). It is up to the person responsible for the interlaboratory study to check if the material selected is suitable or not. If not, the material shall be changed. It is also up to the person responsible for the interlaboratory study to check if the property is normally distributed. When normality of distribution cannot be proven, it is advised to group the data. One can also use comparability techniques, i.e. to compare the average mean differences between laboratories, once the consistency of data coming from these laboratories is also proven graphically.

ISO TS 24498:2022 pdf download – Paper, board and pulps — Estimation of uncertainty for test methods by interlaboratory comparisons